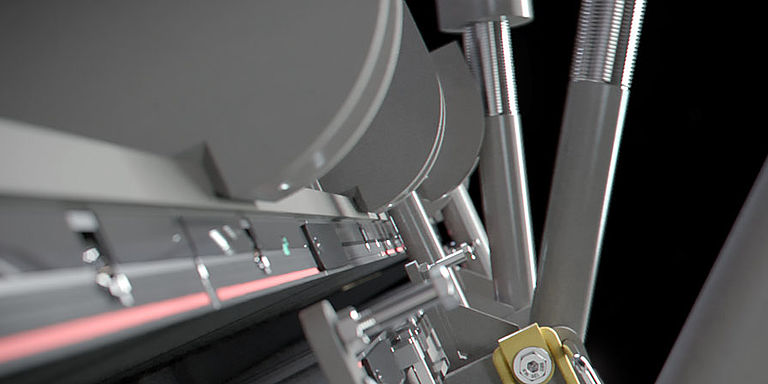

Founded in 1897, WAGENER Vulcanizers GmbH & Co. has decades of experience in the development and manufacture of portable and stationary vulcanizing presses, for splicing and repairing conveyor belts, cables and handrails.

The individual presses which are designed according to the requirements of the client are not only supplied with conventional heating plates by which the temperature is controlled by means of a thermostat or electronic control.

Our product range

• Transportable vulcanizing presses

• Compact vulcanizing presses

• Vulcanizing tools

• Stationary workshop presses

• Special press construction

• Spechial machine construction

For use in mining operations underground portable firedamp-resistant KLIV-Presses are available in steel design in compliance with European Standards EN 50014 and EN 50018. For these presses there are also national licenses in different countries in addition to the license as per the European Standard.

In addition to conveyor belt vulcanizing presses WAGENER Schwelm has also supplied clamping systems for the assembly of conveyor belts in inclined conveyor belt systems for more than 20 years. These clamping systems are necessary for the installation of new conveyor belts, for exchanging belts as well as for repair work in the drive head and take-up set areas. The clamps are designed for retracting and holding conveyor belts even under unfavourable operating conditions.

WAGENER Vulcanizers is ISO 9001 certified - which confirms the high level of quality of WAGENER products.